Downtime for boats, ships, and yachts is expensive. We are boaters ourselves, and we offer expedited service for crisis projects. Remember, we can probably use your broken components as patterns, even if some pieces are missing.

Don't despair! Give us a call - we specialize in cost-effective casting solutions.

HARDWARE:

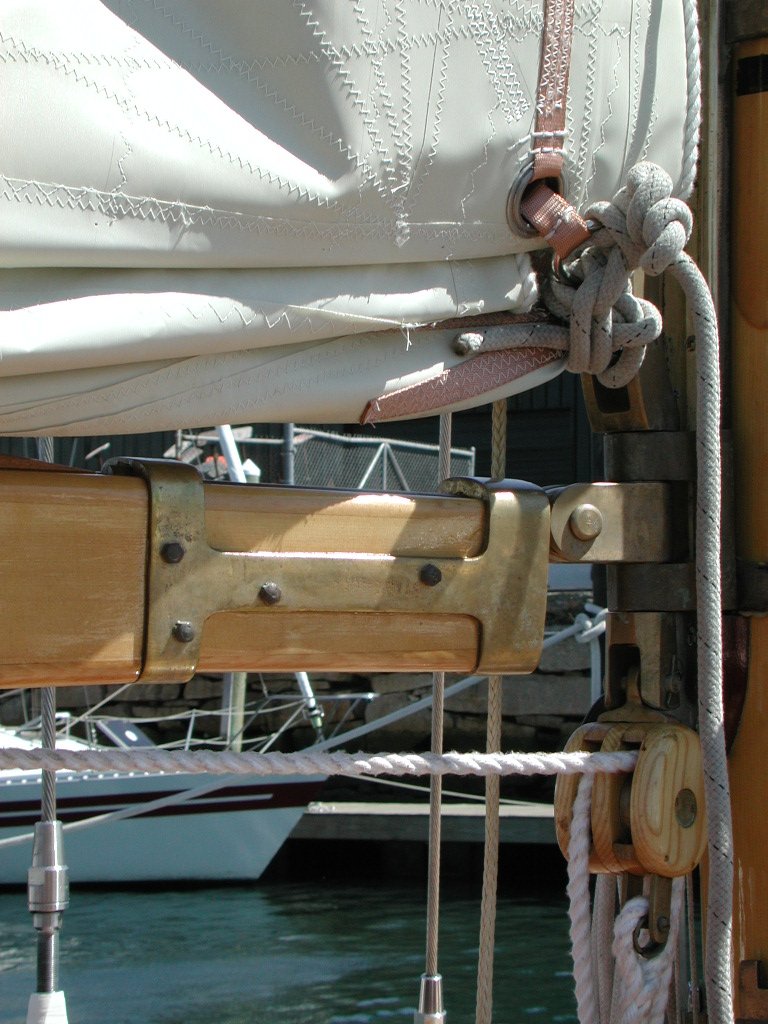

These custom chocks, pintles, and brackets were produced for wooden sailboats, cast in manganese bronze.

PATTERNS

This is the board pattern produced for the castings shown above - carrying all of the component shapes , half on one side of the board, half on the other.

Patterns do not have to be complex to be effective.

The simple hand-shaped glued plywood patterns shown above were for square-section wooden mast brackets. To the right is a simple pattern , and the part, for a forestay tang with a decorative detail.

THE ONAWA PROJECT

In 2000 the Mystic River Foundry provided dozens of custom bronze castings for the restoration of ONAWA, a 1936 Americas Cup racing sailboat. The original steel frames, shown in white, were supplemented with individual bronze frames throughout the hull.

Many of ONAWA's original steel frames were reused.

Bronze keel floors are between each steel frame . Each keel floor required an individual pattern corresponding to the changing hull shape .

Bronze boom-bail with integrally cast attachment cheeks - the pattern was custom-made directly from ONAWA’s new boom.

Internal outhaul sheave and shaft shown on right.

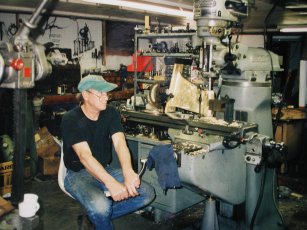

A custom bronze track-slide with bail and spring-loaded locking pin - machined by Don Mason at Wickford Machine, one of a number of specialist machinists the foundry uses .

We also cast multiple repair lengths of track stock.

This strut failed when an incorrect size cutless bearing was press-fitted. We had the machine shop next door close up the crack in their hydraulic press, and then we added putty to increase the strut-head’s wall thickness.

We also made the strut palm considerably thicker - providing excess material to be milled away during alignment and setup.

We make replacement struts for bent, broken, or damaged struts frequently - and we can often have the bent one straightened enough to use as a pattern. In this case the broken one is covered with a thick layer of Bondo to make up for shrinkage as the casting cools and finishing work.

Bring us the broken pieces . We can often salvage enough to save clients both the time and expense of making a pattern by loose-molding the pieces.

PORTLIGHT TRUNKS AND BEZELS

Broken lugs or heavy corrosion are not uncommon on older cast aluminum portlight components.

Both these portlight examples were produced , without patterns, from the originals, which we reconditioned and ‘beefed-up’ to produce greater wall thickness, more robust lugs, and stronger hardware foundations.

MYSTIC RIVER FOUNDRY

Broadway Extension P.O. Box 121 Mystic, CT 06355

tel: 860-536-7634 fax: 860-572-8473

Call or email the Mystic River Foundry for special rates and terms for emergencies .

We will pour metal on Sundays to help you get back in operation.

Foundry owner Sharon Hertzler with patternmaker Keith Brown, inspecting and documenting the gooseneck hardware of an old Americas Cup sailboat.

We can visit your project to make templates, or help you collect the information we need, to produce authentic and accurately sized restoration or reproduction castings.

Don Mason at Wickford Machine, shown here boring a replacement bronze strut we cast, is one of the specialty machinists we use for marine projects .

We typically consult with Don or his colleagues before making any patterns or castings, to ensure that we do not reproduce any problems or design deficiencies present in the original parts.